3D NM-GPR

What is GPR?

Ground Penetrating Radar (GPR) is a subsurface imaging technique that uses ultrawideband electromagnetic (EM) signals to investigate non-conductive materials like soil, asphalt, crushed rock, timber, and ice.

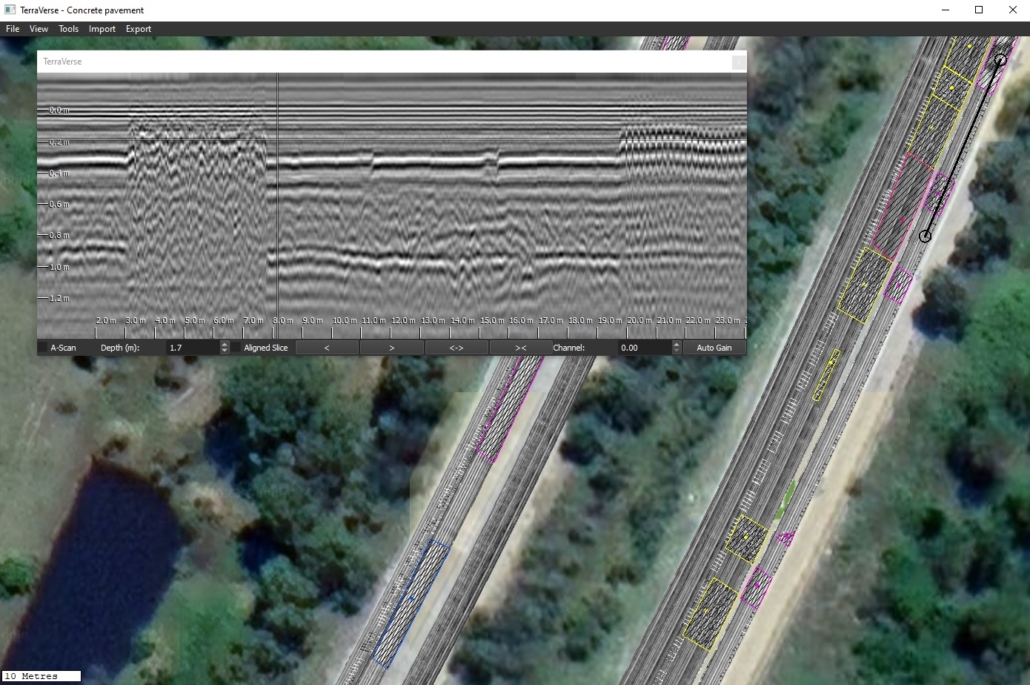

In civil engineering, it is commonly used to locate subsurface utilities, map reinforcing steel, detect voids or defects, and determine as-built details of roads, bridges, and airport pavements.

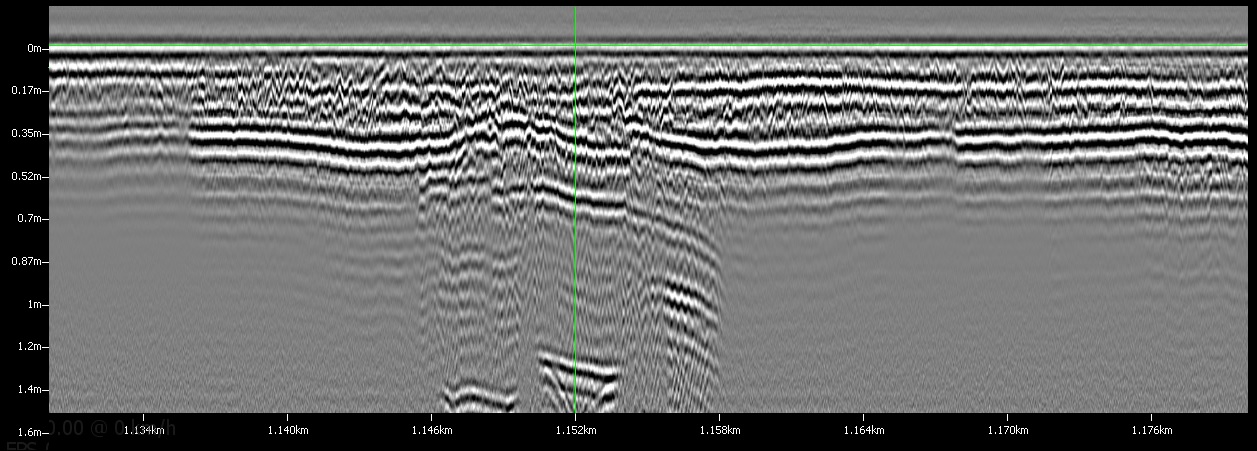

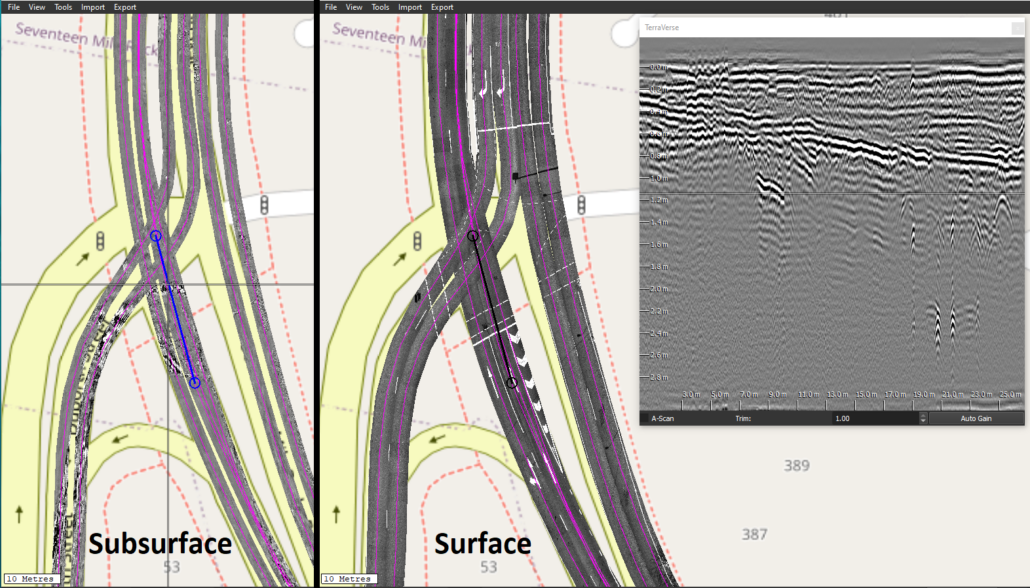

2D GPR data collected over a road culvert

Why 3D?

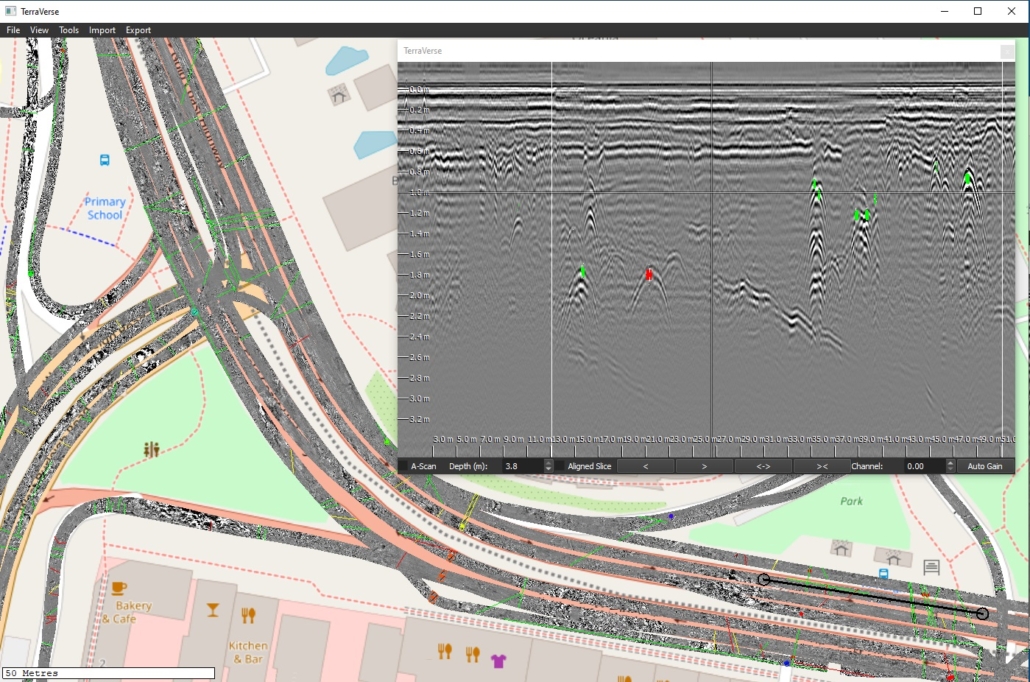

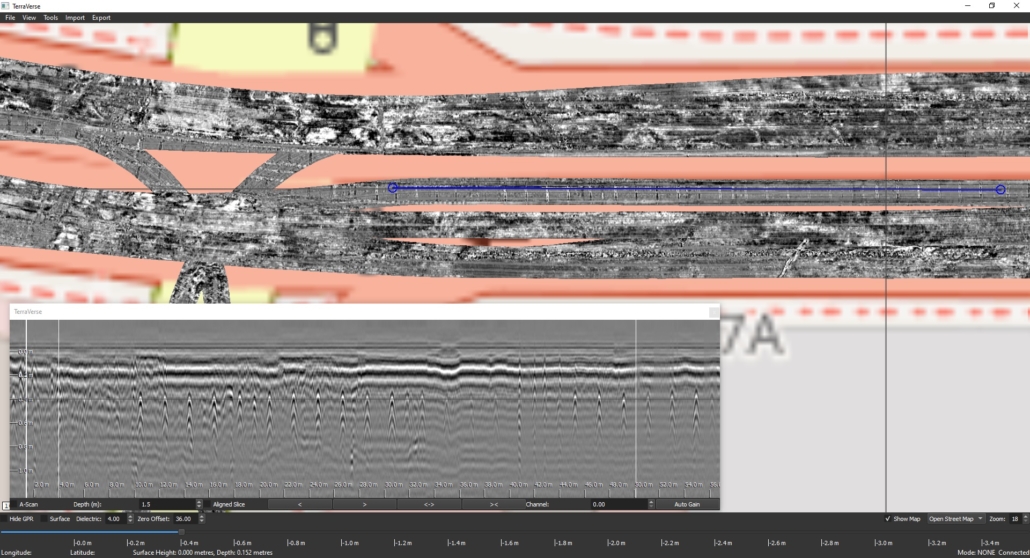

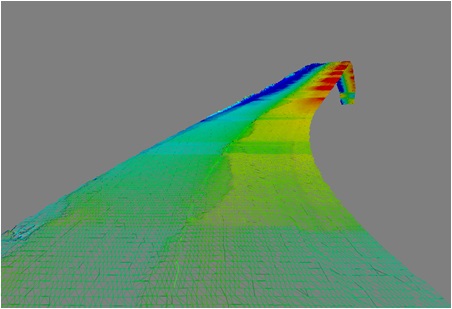

Most GPR systems collect 2D data—single vertical slices along a path. A 3D volume of GPR data can be created by combining multiple 2D scans collected along a grid. The 3D data volume can then be sliced vertically or horizontally to reveal subsurface features at various depths and locations. While effective at small scales, collection of 3D data with a 2D antenna becomes too slow and impractical when investigating large sites.

This is where dedicated 3D GPR systems step in. These capture multiple 2D GPR scans across an antenna array, greatly speeding up data collection. Multiple 3D scans can then be aligned and merged to cover large and complex sites such as roads, bridge decks, airport runways and parks in their entirety.

What is Noise-Modulated GPR?

Noise-Modulated GPR is a type of ground penetrating radar technology. Like impulse and stepped-frequency GPR systems, it emits ultrabroadband signals and records the strength of returning reflections versus elapsed time. However, instead of brief pulses or narrowband tones, it transmits a special type of coded signal. Measured reflections are then cross-correlated with the transmitted signal to generate the familiar GPR A-scan (“trace”) profiles.

Is NM-GPR the same thing?

Partially. NM-GPR refers to a particular type of 3D GPR technology developed by CodedRADAR. While it uses noise-modulated (coded) signals, it also employs novel hardware and sampling techniques in a manner that set it apart from conventional GPR systems.

Why use a different approach?

Fast 3D data collection—especially at highway speeds—places intense demands on GPR hardware. Traditional technologies often can’t keep up without making compromises: reducing speed, sacrificing penetration depth, limiting scan resolution, or lowering data quality.

NM-GPR systems use a combination of novel hardware and sampling methods to gather return signal measurements many thousands of times faster than conventional GPR technologies on multiple simultaneous channels—for blisteringly fast and reliable performance that avoids the usual capacity limitations of traditional technologies. As a result, NM-GPR systems are unmatched for rapid 3D subsurface imaging applications.

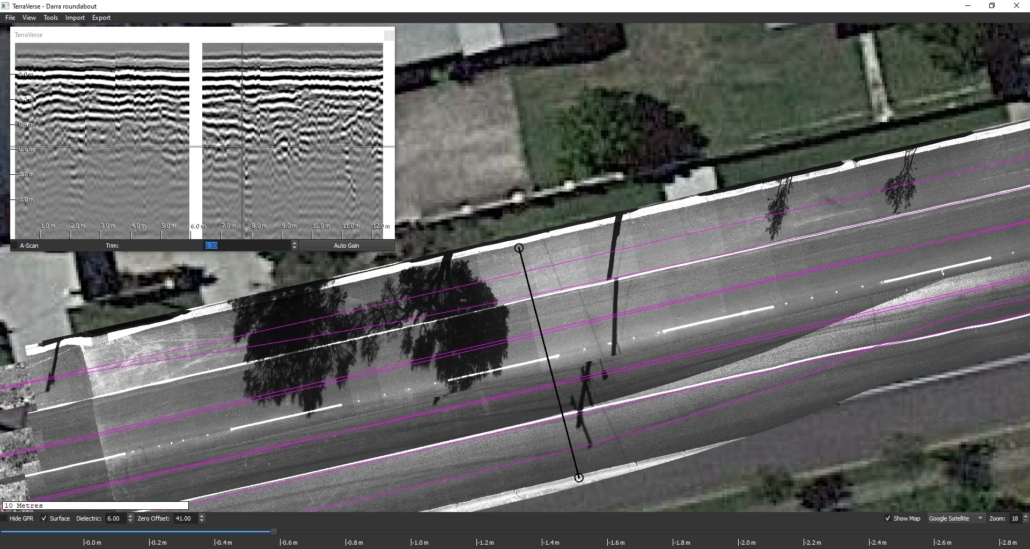

Surface + subsurface

In addition to gathering 3D NM-GPR data, the Kerberos™ and Lynx systems can also capture geolocated surface imagery in the same pass. This provides a wealth of benefits for site investigations, including:

- Detailed snapshot: Provides a detailed record of current surface conditions throughout a site, to document or monitor changes over time.

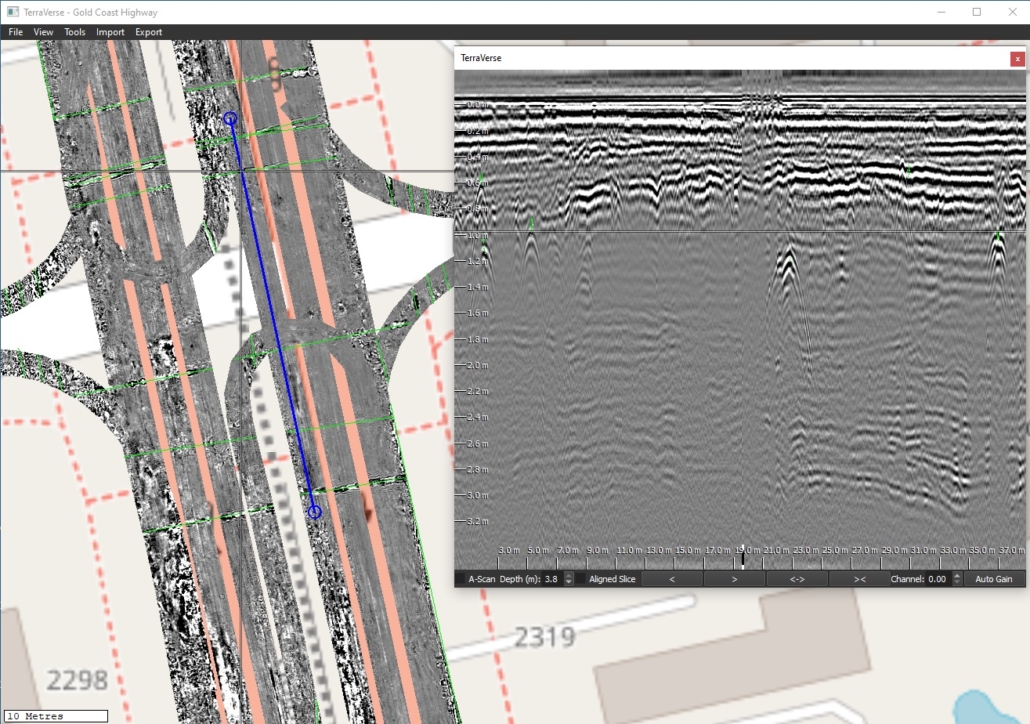

- Relate cause and effect: Compare the location of subsurface defects and subsurface features or changes that may be causing them.

- Better site context: Use positions of manholes, pits, drainage inlets, bridge joints and other surface features to better inform & guide interpretation of 3D GPR data.

- Reliable positioning: As the surface and subsurface images are synchronized, it is possible to locate subsurface features by measuring their location relative to surface features. This feature is particularly useful for locating voids or defects within ‘urban canyons’ where GPS reception is often unreliable.

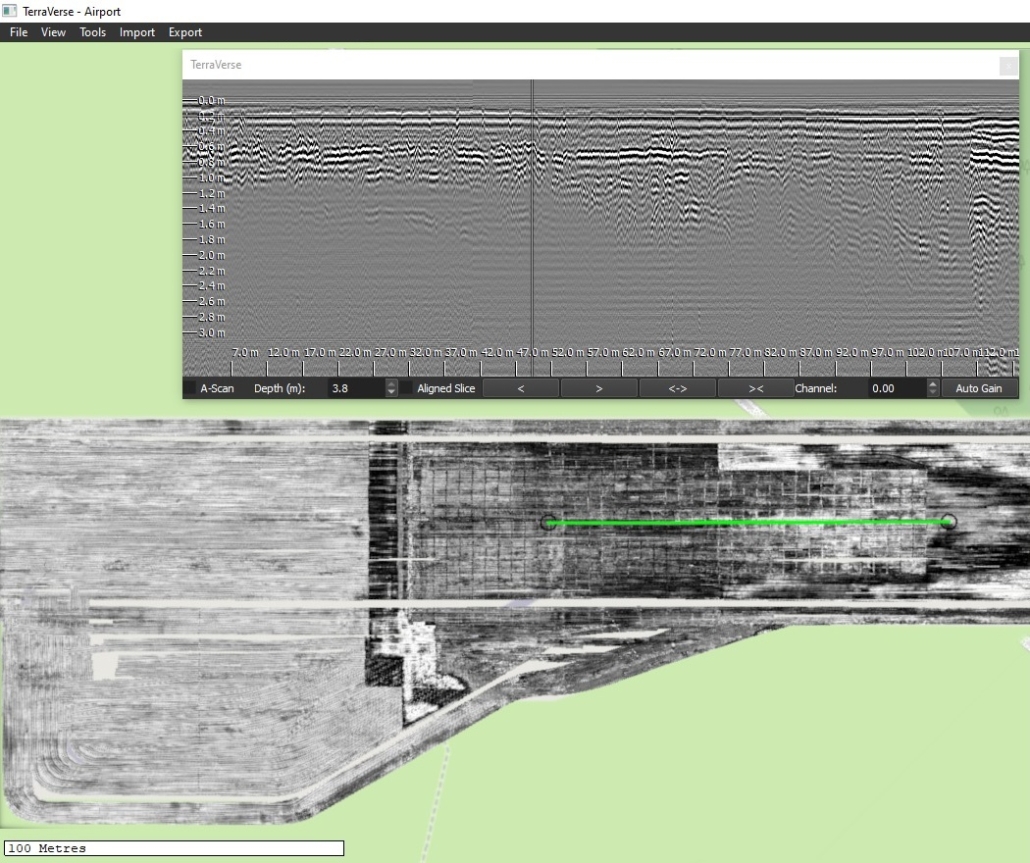

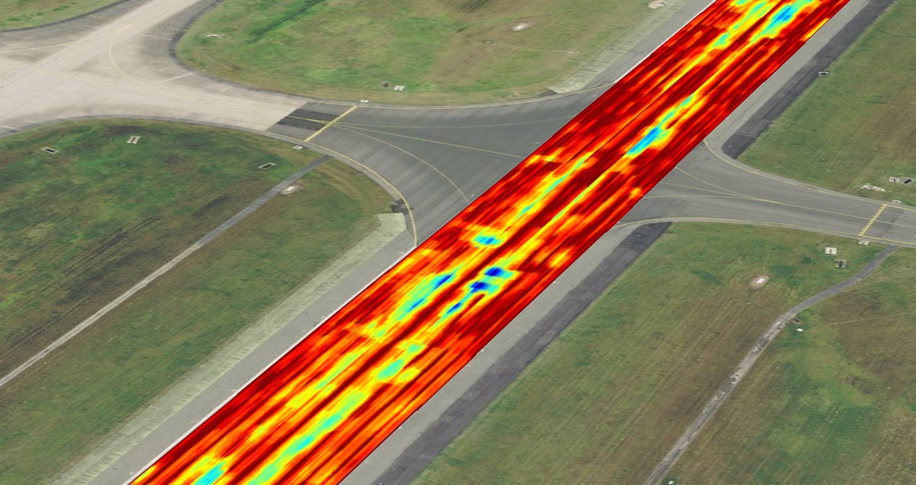

TerraVerse™

CodedRADAR’s TerraVerse™ software enables 3D NM-GPR and surface imagery data from hundreds of scans to be combined into large geospatially-corrected mosaics. This enables large assets such as roads, bridges, airports, ports, parks, gas stations, carparks to be covered in detail and later viewed and analysed as one model, for a holistic understanding of surface and subsurface features.

Auxiliary sensors

For more than 15 years we have created systems that integrate 3D NM-GPR with cameras and a variety of off-the-shelf and custom sensors. This includes sensors used for transverse laser profiling (e.g. measuring ruts), inertial measurement of vehicle motion (IMU), illuminated road surface imaging (i.e. for site context; mapping surface defects), roughness measurements (IRI), LiDAR, and a patented photometric stereo technique.

When you need advanced sensors that complement and make better use of 3D GPR data, CodedRADAR is your one-stop-shop.