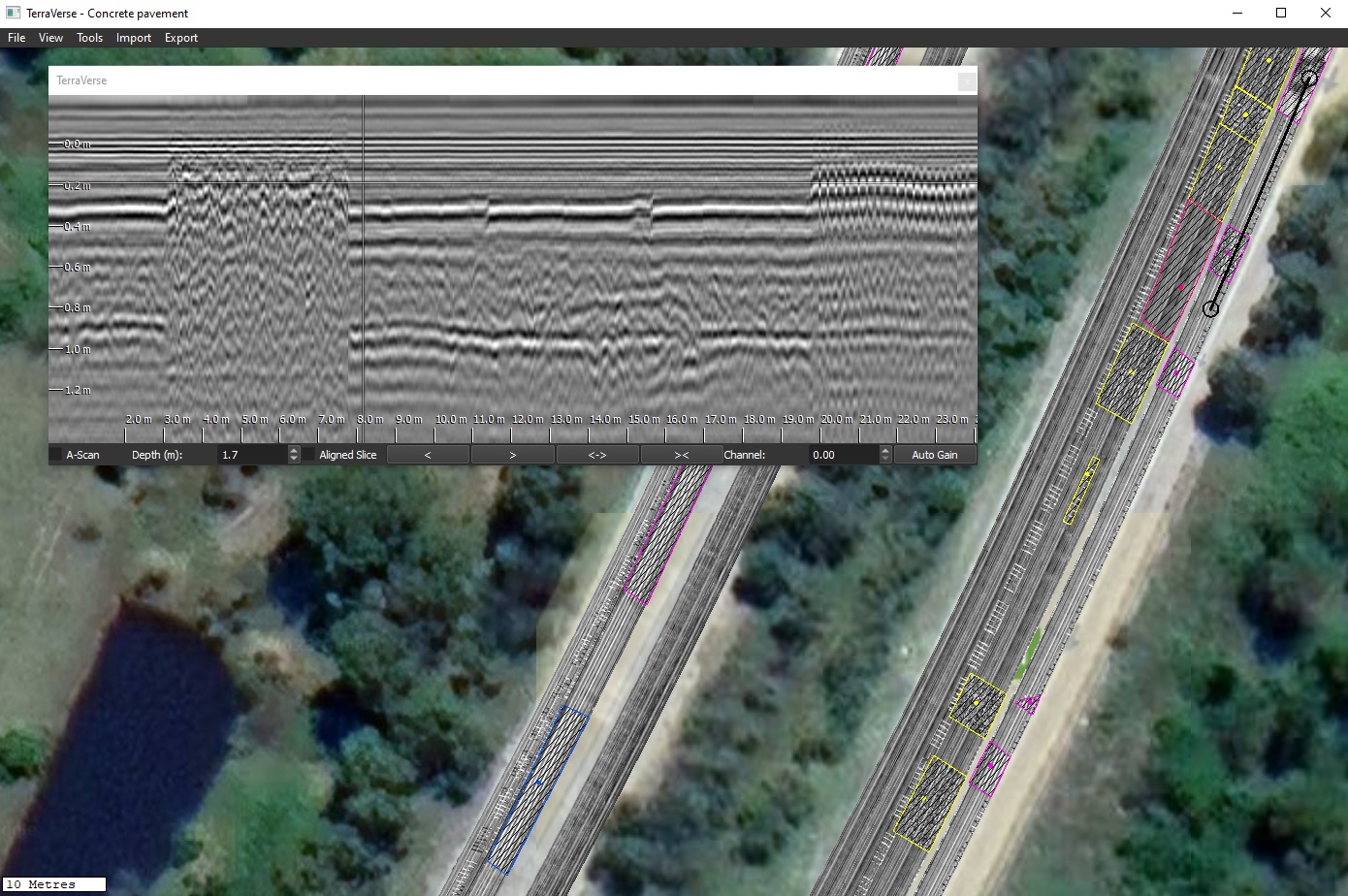

Case study: Locate & identify concrete repairs

- Site: Concrete multi-lane national highway, approx. 8km length to be assessed

- Objective: Determine location and type of concrete repairs

- Approach:

- Kerberos used to scan concrete pavement at traffic speeds

- Scanning performed without traffic control, within normal traffic flow

- Outcomes:

- Approx. 5 hours to scan entire site

- Traffic control not required

- Rebar repairs, tie bars and steel-fibre concrete repairs were clearly visible

- Different concrete repair types were easily identified & distinguished

- Outer boundary of each type tagged in software

- Results export to KML and other formats for client use

- Assessment completed quickly and easily without any pubic disruption

- Client benefits:

- Confidence: Locations & types of pavement repairs were clear and unambiguous within GPR data, giving confidence that they had been reliably identified

- Clarity: Use of 3D GPR enabled extent of each defect type to to be precisely identified, tagged & reported

- Coverage: Pavement lanes covered, providing confidence to proceed with project planning in the covered areas

- Cost & time: Site covered in a fraction of the time and cost of slower 3D or 2D GPR technologies

- Delay & disruption: Traffic-speed 3D GPR collection avoided the significant costs & public disruption of traffic control measures