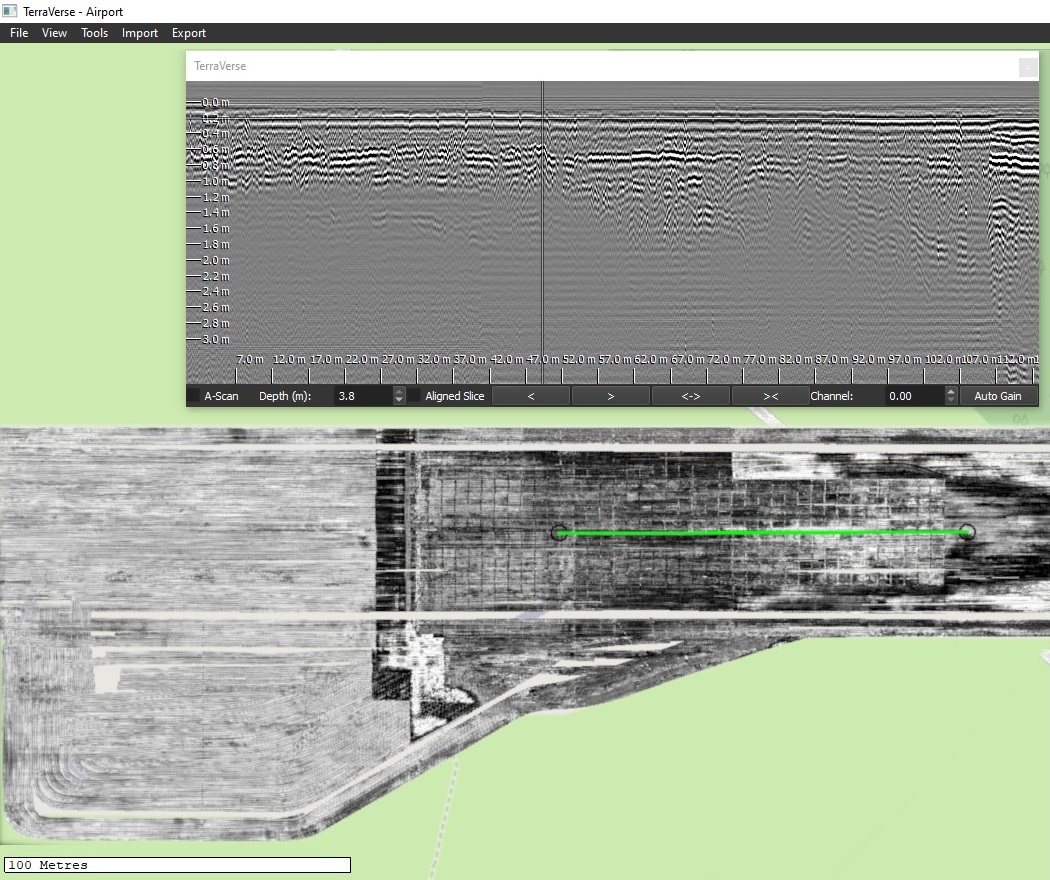

Case study: Assess airport pavement & subgrade

- Site: Main runway of major airport

- Objective: Determine pavement “as-constructed” details and subgrade features, comparing with cores

- Approach:

- Kerberos used to scan runway overnight during period when runway was not being used (after midnight)

- Outcomes:

- Approx. 6.5 hours to scan runway

- Assessment completed without any disruption to airport operations

- > 262,000 m2 of 3D GPR gathered & combined into one model of the site (including overlapping scans)

- Pavement layering & subgrade features from 3D GPR calibrated by comparing to cores and depths reported

- Changes of construction were clearly visible within the 3D GPR plan view at different depths

- 3D GPR data enabled boundaries of differing pavement construction to be clearly delineated, marked & reported

- Cross-sectional profiles across runway pavement (60-120m wide) showed clear variations in pavement thickness

- Features were visible in subgrade to approx. 2.5m deep

- Calibrated layer depths and subgrade findings exported into various formats for client use

- Client benefits:

- Confidence: Complete coverage of airport pavement ensures all pavement variations identified

- Clarity: Use of 3D GPR enabled extent of differing construction types to be clearly seen and precisely identified

- Coverage: Entire site coverage enabled cores at selected locations to be related to depth variations along & across the runway

- Viability: Fast data collection made large-scale assessment viable, as it completely avoided potential disruption to airport operations

- Cost & time savings: Entire site covered in a fraction of the time and cost of slower 3D or 2D GPR technologies